About Us

Desentoys: Your Trusted Partner in Custom Collectible Art Toys

Desentoy is a leading manufacturer specializing in high-quality custom collectible art toys. We partner with brands, designers, and artists worldwide to bring unique creative visions to life.

Our Product Expertise:

We expertly craft a diverse range of collectibles, including Vinyl Toys, PVC & Resin Figures, Action Figures, Plush Toys, Anime Figures, and Life-Size Sculptures. Our mastery extends to various materials such as Copper, Wood, Alloy, and Fiberglass, with specialized finishes like Electroplating. We also produce popular Blind Box toy series.

Our End-to-End Service:

From initial concept and product R&D to meticulous manufacturing and final delivery, we manage the entire process. Our experienced team and rigorous quality control system ensure every piece meets the highest standards. We offer flexible service, including direct-to-fan fulfillment, handling logistics to deliver your product seamlessly to collectors.

Global Collaboration:

We are proud to collaborate with renowned fashion toy companies, art brands, and visionary independent designers across the globe.

Let’s create something extraordinary together.

Our Team

Business Team

Our Customer Service Team is composed of dedicated specialists who serve as your primary point of contact. We are committed to delivering a seamless and supportive experience at every stage—from initial inquiry to post-purchase support. Our team provides expert guidance, addresses all your questions, and ensures your complete satisfaction throughout our partnership.

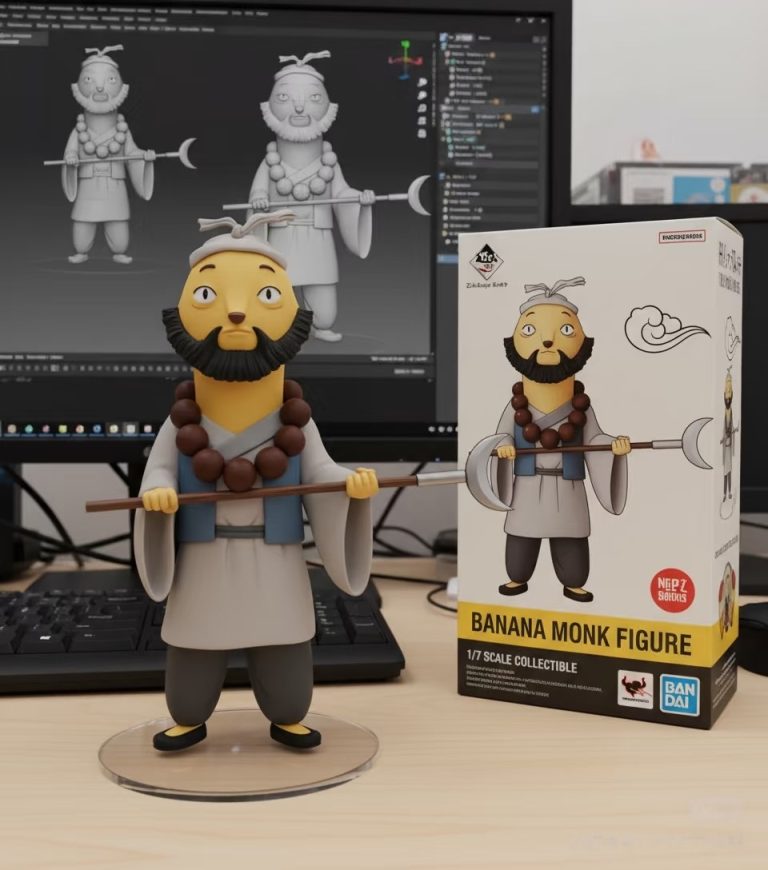

Design Team

Our Design Team brings together skilled graphic and 3D artists dedicated to crafting visually compelling designs. They specialize in transforming your initial concepts into detailed, production-ready models, ensuring your unique vision is perfectly translated from concept to 3D reality.

Molding Department

Our Molding Department specializes in the precise engineering behind every toy. We begin by deconstructing your design into individual components to develop high-precision production molds. Through expert mold assembly and rigorous testing, we ensure each part meets exact specifications for flawless mass production.

Vinyl/Injection Department

At the heart of our production is precision injection molding. Utilizing state-of-the-art machinery, we inject molten vinyl into custom-crafted molds to create figures with exceptional consistency and dimensional accuracy. This controlled process is fundamental to achieving the high-quality, flawless replication that defines every collectible we produce.

Painting Department

Our Painting Department combines meticulous artistry with high-quality, fade-resistant paints to give each vinyl figure its unique character. Through precise color matching and skilled techniques like hand-painting and spray application, we ensure every detail vividly reflects your creative vision, transforming molded forms into vibrant collectibles.

Assembly Department

The Assembly Department represents the final and crucial stage in the manufacturing process. Here, our skilled technicians carefully join all components, ensuring a seamless fit and flawless finish. This meticulous attention to detail guarantees that every figure not only meets but exceeds our rigorous quality standards, resulting in a polished final product ready for collection.

Quality Control Department

As the guardian of quality, our Quality Control Department conducts meticulous inspections at every stage of production. From raw materials to final assembly, our dedicated team enforces stringent standards to ensure that each vinyl figure meets both our specifications and your expectations. Only products that pass this rigorous process are approved for delivery.

Packing Department

The Packing Department executes the final step before your collectibles begin their journey. Using custom-fit packaging and protective materials, we ensure that every figure arrives in perfect condition. We combine secure transit assurance with brand-aligned presentation, setting the stage for a memorable unboxing moment.

what makes us different

Desentoy Competitive Advantages

Certified Material Safety

We ensure complete compliance with international safety standards. All raw materials hold CE and CPSIA certifications, and our toys are manufactured and painted with eco-friendly materials that meet EN71 and CA65 requirements.

One-Stop Service

Our integrated production line covers the entire process—from artwork design, 3D prototype printing, molding, and mass production, to packaging and final delivery. We also support drop shipping directly to your customers

Fast & Flexible Customization

We can turn your 2D design or 3D file into a physical prototype within 7–9 working days, balancing high quality with shorter lead times.

Rigorous Quality Control

We confirm every production detail with you before mass production begins. Upon completion, our QC team conducts a final inspection and can provide photos and detailed reports upon request.

Globally Recognized Audits

Our factory has passed strict on-site verifications by leading international inspection bodies, including SGS, Sedex, TÜV Rheinland, and Disney compliance audits.

Low Minimum Order Quantity (MOQ)

· Sample: 1 pc · Custom resin figure: 50 pcs · Custom vinyl figure: 100 pcs · Custom plastic figure: 1000 pcs

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.